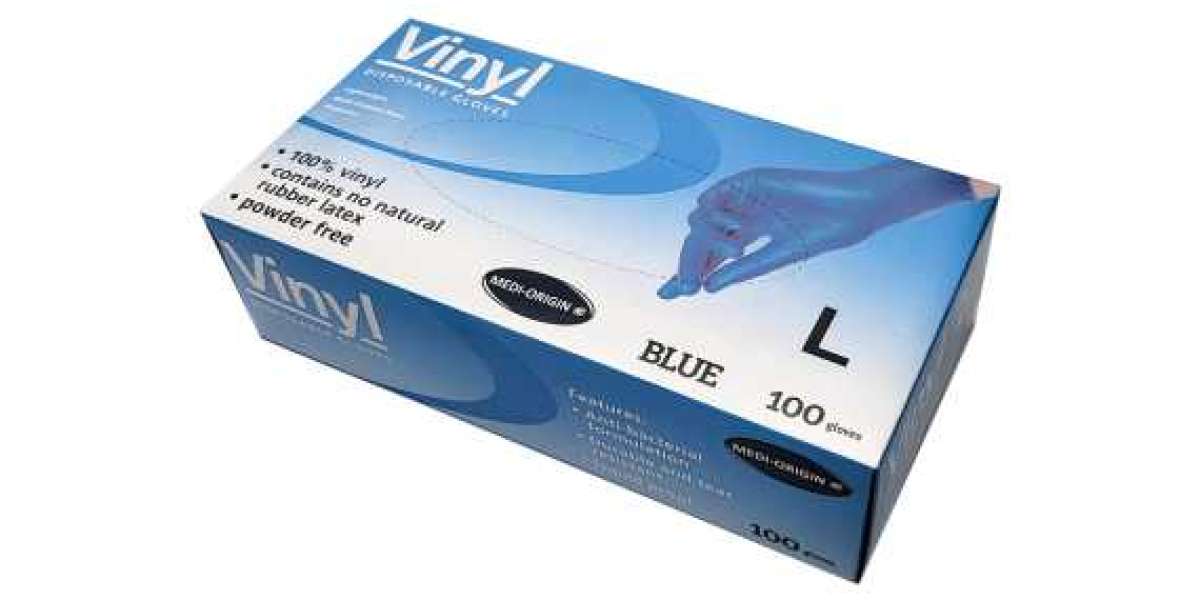

Vinyl medicated gloves have become essential in numerous professional fields, particularly within the healthcare sector. These gloves are favored for their affordability and versatile functionality, providing a reliable barrier against contaminants. Manufactured from polyvinyl chloride (PVC), vinyl gloves offer a smooth and comfortable fit, making them suitable for prolonged use. Their utility extends beyond healthcare, finding applications in food handling, cleaning, and various industrial settings. An increasingly popular choice, Vinyl Medicated Gloves help maintain stringent hygiene standards while offering ease of use. This article explores the different types of Vinyl Medicated Gloves, including medicated, powder-free, and disposable variants, highlighting their unique benefits and applications.

Vinyl Medicated Gloves

Vinyl-medicated gloves stand out due to their built-in antimicrobial properties, offering protection against harmful microorganisms. These gloves are particularly useful in medical settings where hygiene is paramount. Made from polyvinyl chloride (PVC), they provide a smooth texture that enhances comfort during extended use. Incorporating antimicrobial agents helps reduce the risk of cross-contamination, ensuring a safer environment for patients and healthcare workers.

Additionally, these gloves maintain the affordability and ease of use typical of Vinyl Medicated Gloves, making them a cost-effective choice for various professional settings. Their application is not limited to healthcare; they are also beneficial in laboratories and industrial environments where the prevention of microbial spread is crucial.

Benefits of Vinyl Medicated Gloves

Vinyl-medicated gloves offer enhanced protection due to their antimicrobial properties, reducing the likelihood of pathogen transmission. They provide a comfortable fit, which is crucial for prolonged use, and the smooth texture of polyvinyl chloride (PVC) enhances wearability. These gloves are particularly beneficial in environments where hygiene is critical, such as healthcare settings, laboratories, and industrial applications.

The integration of antimicrobial agents helps maintain a cleaner working environment, decreasing the risk of cross-contamination. Additionally, the cost-effectiveness of these gloves makes them an attractive option for various professional fields. Vinyl material's flexibility and tactile sensitivity ensure that tasks requiring precision can be performed efficiently, while the gloves' durable nature provides reliable protection.

Vinyl Powder Free Gloves

Vinyl powder-free gloves represent a significant advancement in hand protection for industries where maintaining a sterile and allergen-free environment is crucial. By eliminating the powder traditionally found in some disposable gloves, these options offer enhanced safety and comfort for both users and the environments in which they are used. Here's a closer look at the key benefits of these gloves:

Eliminating Powder-Related Contamination Risks

The absence of powder in these gloves is a primary advantage, particularly in sensitive settings like medical and food handling. Powder particles can act as carriers for allergens and contaminants, posing a risk to patients, food products, and the overall cleanliness of the environment. Vinyl Powder Free Gloves mitigate this risk, contributing to a more sterile and safer workspace.

Minimizing Allergic Reactions for Sensitive Users

For individuals with latex allergies or sensitivities to glove powder, powder-free Vinyl Medicated Gloves offer a comfortable and safe alternative. The material itself, polyvinyl chloride (PVC), is generally well-tolerated, and the absence of powder further reduces the potential for skin irritation and allergic reactions, promoting user well-being and compliance with safety protocols.

Maintaining Protection and Durability

Despite being powder-free, these gloves retain the essential protective qualities associated with traditional Vinyl Medicated Gloves. They provide a reliable barrier against various substances and help protect the wearer's hands during tasks. The durable nature of PVC ensures that the gloves can withstand the demands of different applications without easily tearing or compromising their integrity.

Enhancing Comfort and Ease of Use

The smooth, powder-free interior of these gloves contributes to increased user comfort. Without the gritty feel of powder, the gloves are easier to don and doff, and they reduce the likelihood of skin irritation during prolonged use. This enhanced comfort can lead to improved dexterity and efficiency, especially in tasks requiring fine motor skills.

Broad Utility Across Hygiene-Critical Sectors

The benefits of powder-free Vinyl Medicated Gloves make them suitable for a wide range of industries where hygiene and safety are paramount. From healthcare facilities and laboratories to food processing plants and catering services, these gloves provide a reliable hand protection solution that meets stringent standards and contributes to a cleaner and safer working environment.

Advantages of Vinyl Powder-Free Gloves

Vinyl powder-free gloves minimize the risk of contamination and allergic reactions, making them ideal for environments requiring high hygiene standards. The absence of powder reduces the likelihood of powder-related skin irritation, which is particularly beneficial for individuals with sensitive skin. These gloves provide a smooth, comfortable fit, which enhances user comfort and dexterity during tasks that demand precision.

Made from polyvinyl chloride (PVC), they retain traditional Vinyl Medicated Gloves' durability and protective qualities while eliminating potential powder residues. Their versatility makes them suitable for various applications, including medical, food handling, and industrial settings, where maintaining cleanliness is critical. Additionally, the ease of donning and removing these gloves adds to their practicality in fast-paced environments.

Disposable Vinyl Medicated Gloves

Disposable Vinyl Medicated Gloves are essential for requiring frequent glove changes, offering convenience and cost-effectiveness. Commonly used in healthcare, food preparation, and various industries, these gloves ensure a fresh pair is always available, significantly reducing contamination risks. Their single-use nature aligns well with settings where hygiene is a top priority, such as hospitals and kitchens.

While their disposability raises environmental concerns, advancements in biodegradable options are being explored to address sustainability issues. Made from polyvinyl chloride (PVC), these gloves provide reliable protection and ease of use, making them a practical choice for short-term applications. They are available in various sizes and thicknesses, ensuring a suitable fit for different tasks.

Why Choose Disposable Vinyl Medicated Gloves?

Disposable Vinyl Medicated Gloves offer a practical and economical solution for tasks necessitating frequent glove changes. Their single-use nature aligns with environments prioritizing hygiene, such as hospitals, laboratories, and food preparation areas, where contamination control is crucial. Made from polyvinyl chloride (PVC), these gloves ensure reliable protection while maintaining ease of use. The sizes and thicknesses allow for a tailored fit, enhancing user comfort and dexterity.

Additionally, disposable Vinyl Medicated Gloves cater to various sectors, balancing functionality and cost-effectiveness. With ongoing advancements in biodegradable materials, these gloves are evolving to address environmental concerns, making them a forward-looking choice in disposable protective wear.

Comparing Vinyl Medicated Gloves to Other Materials

Vinyl Medicated Gloves offer a distinctive advantage by being latex-free, reducing the risk of latex-induced allergic reactions. While they may not match latex gloves' elasticity and comfort, they are a cost-effective alternative suitable for many applications. Compared to nitrile gloves, Vinyl Medicated Gloves are generally less durable but more affordable, making them ideal for tasks that do not require high puncture resistance.

Nitrile gloves, known for their strength and chemical resistance, are more expensive. Each type of glove has its specific benefits, making the choice dependent on the particular needs of the task, whether it be medical, food handling, or industrial. The selection criteria often include considerations of comfort, durability, and cost.

Factors to Consider When Choosing Vinyl Medicated Gloves

When selecting Vinyl Medicated Gloves, several key considerations ensure optimal performance and suitability for the intended use. The application, such as medical, food handling, or industrial, determines the appropriate type of glove. Size and thickness influence comfort, dexterity, and protection levels. Assessing the presence of any specific features, like powder-free or medicated options, is essential for meeting hygiene and safety requirements.

Additionally, the material quality, often indicated by industry certifications, plays a vital role in the gloves' durability and effectiveness. Choosing gloves from reputable sources can also ensure adherence to safety standards, providing peace of mind in professional settings.

Ensuring Quality in Vinyl Medicated Gloves

Vinyl Medicated Gloves' quality can be ascertained through rigorous testing and certification processes that align with industry standards. Various factors influence the performance and reliability of these gloves, including the consistency of the polyvinyl chloride (PVC) material used in their manufacture. Gloves that pass stringent tests for tensile strength, elasticity, and puncture resistance demonstrate higher durability and reliability.

Adherence to standards such as EN 455, which covers medical glove requirements, or EN 374, relating to chemical risks, is essential for ensuring safety and effectiveness.

Attention to manufacturing processes, such as proper molding techniques and quality control measures, also plays a significant role. Choosing gloves from reputable suppliers who offer detailed product specifications and certifications can further ensure high-quality standards. Regular audits and third-party verifications contribute to maintaining the integrity of the gloves, assuring their protective capabilities in various professional settings.

Innovations in Vinyl Glove Technology

Recent innovations in vinyl glove technology have focused on enhancing performance and user comfort. Efforts to improve material formulations have resulted in gloves with better tactile sensitivity and flexibility, making them more suitable for precision tasks. Advances in antimicrobial properties have also been integrated, boosting their effectiveness in medical and laboratory settings.

Additionally, manufacturers are experimenting with eco-friendly materials, aiming to reduce the environmental impact of disposable gloves. Enhanced manufacturing processes, such as more precise molding techniques, ensure a consistent quality that meets stringent industry standards. These technological strides contribute to Vinyl Medicated Gloves' versatility and growing adoption across various professional fields.

The Future of Disposable Vinyl Gloves

The development of Disposable Vinyl Gloves is increasingly focused on sustainability and eco-friendly solutions. Research into biodegradable materials aims to address environmental concerns associated with disposable gloves. Innovative recycling programs are being explored to minimize waste and promote circular economies. Beyond environmental considerations, advancements in glove design are set to improve functionality and user experience. Enhanced formulations are being developed to increase tactile sensitivity and flexibility, catering to tasks that require high precision.

There is also a growing emphasis on integrating advanced antimicrobial properties, enhancing their effectiveness in healthcare and laboratory settings. Efforts to reduce the environmental footprint do not compromise the gloves' protective qualities, ensuring they remain reliable for various professional applications. These advancements indicate a promising future for Vinyl Medicated Gloves, balancing the need for effective protection with sustainability goals.

Conclusion

Vinyl Gloves offer a valuable combination of affordability and antimicrobial protection, making them essential in Australian healthcare and beyond. While powder-free options address contamination concerns and disposable variants provide convenience, ongoing innovations aim for enhanced comfort and sustainability. Understanding the specific needs of the application and considering factors like quality and certifications ensures the appropriate selection of Vinyl Medicated Gloves, contributing to safer and more hygienic practices across various industries in Australia.

Frequently Asked Questions

What distinguishes vinyl medicated gloves from standard vinyl gloves and what specific benefits do the antimicrobial properties offer in Australian healthcare settings?

Medicated Vinyl Gloves incorporate antimicrobial agents within the material, providing an extra layer of protection against harmful microorganisms, which is particularly beneficial in reducing cross-contamination risks in Australian hospitals and clinics.

How do vinyl powder-free gloves address concerns related to contamination and user comfort in sensitive environments like Australian food handling and medical facilities?

The absence of powder in these gloves eliminates the risk of powder-related contamination, crucial in sterile environments, and also minimizes potential allergic reactions, enhancing comfort for users with sensitive skin in Australian workplaces.

Considering the various materials available for gloves, what are the key advantages of choosing disposable Vinyl Medicated Gloves for tasks requiring frequent changes?

Disposable Vinyl Medicated Gloves offer a cost-effective and convenient solution for tasks needing frequent glove changes, aligning with strict hygiene protocols in Australian healthcare, food service, and other industries where contamination control is paramount.

What are some critical factors that professionals in Australia should consider when selecting Vinyl Medicated Gloves to ensure they meet the specific requirements of their intended use?

Key considerations include the application (medical, food handling, industrial), required size and thickness for optimal comfort and protection, the necessity of features like powder-free or medicated options, and the material quality indicated by relevant certifications in Australia.

What are some of the recent innovations in vinyl glove technology that are aimed at improving their performance, user experience, and environmental impact in Australia?

Innovations include improved material formulations for better tactile sensitivity and flexibility, enhanced antimicrobial properties, and the exploration of eco-friendly materials and recycling programs to address sustainability concerns in the Australian context.

Related Business Listings |